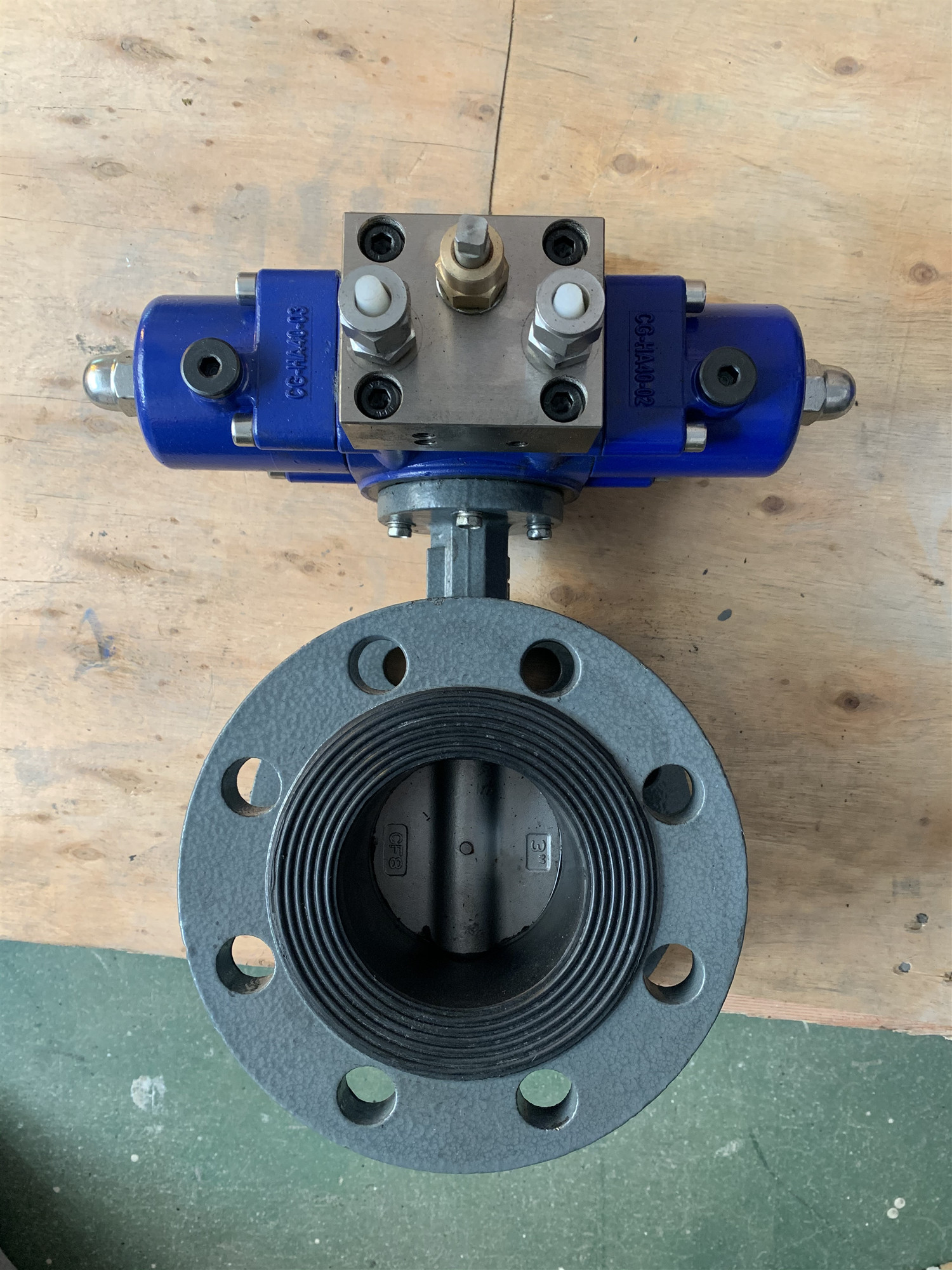

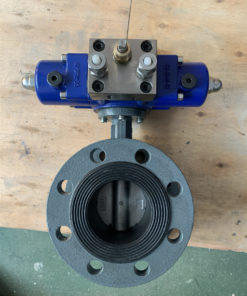

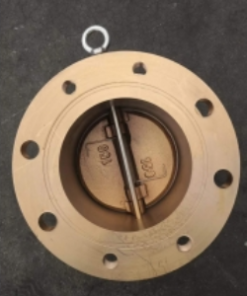

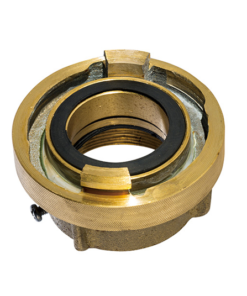

Bronze/Stainless Steel/Copper Electric/Hydraulic/Pneumatic Marine flanged ball valves Ball Valve for Ship

Marine Bronze/Stainless Steel/Copper Electric/Hydraulic/Pneumatic Ball Valve for Ship/Vessel/Boat

Can be customized to electric/hydraulic/Pneumatic type

Customized size like DN65, DN100,DN200…etc

Bronze/Stainless Steel/Copper Electric/Hydraulic/Pneumatic Marine ball valves for Ship

Marine Ball valves Bronze/Stainless Steel flanged Ball Valve for ship

What’s more, The Marine ball valves is carefully polishing and testing before leaving factory to ensure the performance.

In addition, Copper&Bronze/Stainless Steel material has longer service life for your pipes&vessel.

Classification of flanged ball valves by structure

1 Floating ball valve

The ball of a ball valve is floating, and under the action of medium pressure, the ball can generate a certain displacement and tightly press on the sealing surface of the outlet end,

ensuring the sealing of the outlet end. The floating ball valve has a simple structure and good sealing performance,

While the ball bears all the load of the working medium and is transmitting to the outlet sealing ring.

Therefore, it is necessary to consider whether the sealing ring material can withstand the working load of the ball medium. This structure is widely using for medium and low pressure ball valves

2. Fixed ball valve

The ball of a flanged ball valve is fixed and does not move under pressure.

Fixing ball valves are equipped with floating valve seats, which move when subjecting to medium pressure, causing the sealing ring to tightly press against the ball to ensure sealing.

Usually, bearings are installing on the upper and lower shafts of the ball, with small operating torque, suitable for high-pressure and large-diameter valves.

In order to reduce the operating torque of ball valves and increase the reliability of sealing, oil sealed ball valves have emerged in recent years.

They not only inject special lubricating oil between the sealing surfaces to form an oil film,

which enhances the sealing performance but also reduces the operating torque, making them more suitable for high-pressure large-diameter ball valves

Product polishing Video:

| Weight | 600 kg |

|---|---|

| Dimensions | 185 × 110 × 90 cm |

| Material | Bronze&Copper&Stainless Steel/Steel |

| Size | Customized(DN65,DN100,DN200…etc) |

| Certificate | ABS, BV, LR, RINA, DNV, CCS, etc… |

| Package | Standard Exporting Wooden Box Packing, easy for forklift to transport. |

| Accessories | Rubber Ring&Covers |

Reviews

There are no reviews yet.

Only logged in customers who have purchased this product may leave a review.